Newtec Power Equipment Co., Ltd.

English

Views: 0 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

A Power Generator plays a critical role in modern life, from emergency backup systems to primary energy sources in remote locations. When grid power fails or simply doesn’t exist, generators step in to keep electricity flowing. They power homes during outages, support businesses, and keep industrial operations running smoothly. Understanding how a power generator works helps users choose the right equipment, operate it safely, and maximize efficiency. By converting mechanical motion into usable electrical energy through electromagnetic principles, generators provide a reliable bridge between fuel, motion, and electricity we depend on every day.

A generator is a device that turns mechanical energy into electrical energy. Think of it as a machine that makes electricity flow when you need it. It doesn’t create electricity out of nowhere; it channels energy from engines, turbines, or other sources. Generators work by moving a magnetic field around wire coils. This motion pushes electrons along, producing an electric current. We call this process electromagnetic induction, and it’s the core of how generators create electricity.

They are everywhere. Homes rely on small backup generators during blackouts. Businesses use larger units to keep equipment running. Construction sites often bring portable generators to power tools. In remote areas, generators act as the main electricity source where power lines don’t reach.

| Application Type | Typical Use Case |

|---|---|

| Residential | Backup power for homes, appliances |

| Commercial | Offices, shops, small factories |

| Industrial | Factories, warehouses, heavy machinery |

| Construction | Portable power for tools on-site |

| Remote Areas | Cabins, off-grid communities |

Generators are especially valuable during outages. They keep lights on, computers running, and essential machines operating. They also provide independence from unreliable grids, letting people or businesses stay productive anywhere.

Electricity in a generator starts from a simple idea: moving magnets create a current. Michael Faraday discovered this in 1831. He found that moving a conductor through a magnetic field forces electrons to flow.

Think of it like a water pump. It doesn’t create water, but pushes it through pipes. A generator does something similar with electricity. By moving wire coils or magnets, it pushes electrons along, producing usable power.

A generator needs mechanical energy first. This comes from a prime mover, which could be an engine, wind turbine, hydroelectric system, or gas turbine. It spins the rotor or armature inside the generator.

The rotor moves inside the stationary stator. This movement creates a changing magnetic field, which pushes electrons through the stator’s wire coils. That’s how electricity flows.

Generators can produce alternating current (AC), where voltage flips direction periodically, or direct current (DC), which flows steadily in one direction. The type depends on the design and intended application.

Mechanical to Electrical Flow:

| Prime Mover | How It Spins the Rotor | Electricity Type |

|---|---|---|

| Engine (gas/diesel) | Rotating shaft drives armature | AC or DC |

| Wind turbine | Blades turn rotor inside stator | AC |

| Hydroelectric | Water flow spins turbine rotor | AC |

| Gas turbine | High-speed rotor creates magnetic field | AC or DC |

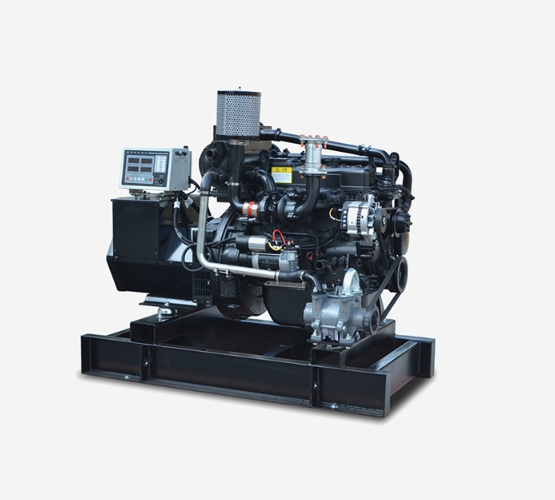

The engine is the heart of any generator, providing the mechanical energy needed to produce electricity. Generators use different engine types, including gasoline, diesel, natural gas, propane, and bi-fuel systems. Each fuel type affects efficiency, runtime, and maintenance requirements. OHV (Overhead Valve) engines place valves on the cylinder head, offering improved airflow, higher efficiency, and longer lifespan. Non-OHV engines mount valves differently and may be simpler but less efficient. Many engines feature a Cast Iron Sleeve (CIS) lining to reduce friction, prevent wear, and enhance durability. Engine size directly influences the maximum power output, meaning bigger engines can drive higher-capacity generators.

Fuel type impacts efficiency, runtime, and maintenance

OHV engines run cooler, last longer, and require fewer repairs

CIS lining improves durability and reduces friction

Engine size determines electricity production capacity

The alternator is responsible for converting mechanical motion from the engine into electrical energy. It contains a rotor (or armature) that spins inside the stator, creating a changing magnetic field. Bearings reduce friction, while field windings generate the magnetic flux needed to induce current. Brushless alternators are increasingly preferred due to minimal maintenance and longer life, although traditional brush alternators are still widely used. Housing materials also matter: metal housings are stronger and withstand heat better, while plastic housings are lighter but more prone to damage over time.

Converts engine motion into usable electricity

Rotor spins inside stationary stator to induce current

Brushless designs reduce maintenance and improve efficiency

Metal housings provide durability and heat resistance

The fuel system ensures a continuous supply of energy to the engine. It typically includes fuel tanks, pumps, injectors, ventilation pipes, overflow connections, and water separators. Portable generators have smaller, built-in tanks, while industrial or commercial units may require large external tanks. Efficient fuel management ensures longer runtime, better performance, and fewer interruptions.

Tank size should match generator load and runtime

Fuel pumps and injectors maintain consistent fuel flow

Ventilation prevents pressure buildup and fuel vapor hazards

Water separators protect the engine from contamination

The voltage regulator maintains stable output voltage, even under changing load conditions. It converts a portion of AC voltage into DC and feeds it to the exciter windings on the rotor. Rotating rectifiers help convert the electricity back to AC as needed, ensuring smooth, continuous power. Without a voltage regulator, connected devices could experience fluctuations, which may damage sensitive equipment.

Stabilizes voltage under varying electrical loads

Converts AC to DC for rotor excitation

Maintains reliable and consistent electricity output

Generators produce significant heat during operation, which must be managed to prevent damage. Cooling systems include fans, radiators, water, or hydrogen-based cooling. Residential units mostly use air or water cooling, while large industrial generators often employ hydrogen-cooled systems for higher efficiency. Proper heat management prolongs generator life and maintains performance.

Removes heat from engine and alternator components

Air/fan cooling for small units; water or hydrogen for large units

Prevents overheating and protects electrical components

Generators emit toxic gases, including carbon monoxide and hydrocarbons. Exhaust systems safely remove these emissions, routing them outdoors and away from buildings. Pipes often include flexible connectors to reduce vibration and prevent structural damage. Correct installation ensures safety, compliance with regulations, and improved air quality around the generator.

Direct fumes safely outside the building

Flexible piping minimizes vibration and wear

Follow environmental safety standards and local regulations

Lubrication is essential to reduce friction between moving parts, especially in the engine. Proper oil levels and quality keep the generator running smoothly, prevent overheating, and extend its lifespan. Routine inspections, timely oil changes, and leak monitoring are critical to long-term performance.

Check oil levels regularly, typically every 8–12 hours of operation

Change oil according to manufacturer guidelines

Prevent leaks to avoid engine damage

Generators rely on batteries for starting. The charger maintains optimal float voltage to prevent overcharging or undercharging. A well-maintained battery ensures reliable startup during emergencies. Some units include dual batteries for redundancy in critical applications.

Provides power to start the generator engine

Charger maintains correct voltage levels

Prevents battery failure during emergency use

The control panel is the operator’s interface, offering full control and monitoring. It typically includes electric start and stop functions, gauges for oil pressure, coolant temperature, battery voltage, engine speed, and runtime. Advanced panels may feature frequency and phase switches, automatic alarms, and safety shutdown mechanisms.

Electric start and shutdown controls

Engine and generator gauges for monitoring performance

Phase and frequency selectors for AC generators

Safety indicators and alarms

The main frame supports all components and ensures stability. It provides proper grounding for safety. Portable generators focus on lightweight design and easy transport, while industrial units prioritize strong, rigid frames to support heavy engines and alternators. Proper housing also shields components from dust, moisture, and physical damage.

Provides structural support for all components

Ensures safe grounding and electrical isolation

Portable design for small units, durable for industrial units

Protects internal components from environmental hazards

Generators turn mechanical energy into electricity through a series of coordinated steps. Understanding this step-by-step process helps explain how they power homes, businesses, and industrial equipment reliably.

The process starts at the prime mover, such as an engine, wind turbine, or hydro turbine. This source provides the mechanical force that spins the rotor or armature inside the generator. The speed and strength of this rotation directly affect the electrical output.

As the rotor spins, it generates a magnetic field around itself. In some generators, this is done using field windings energized by DC current. The moving magnetic field interacts with the stationary stator coils, setting the stage for electricity generation.

The stationary stator contains copper wire coils. The moving magnetic field induces a voltage in these coils, producing an electric current. This is the core principle of electromagnetic induction, discovered by Michael Faraday.

Analogy: Think of it like water flowing through a pump—motion forces the current to move, producing usable electricity.

The voltage regulator monitors the generator’s output. If load changes occur, it adjusts the excitation to maintain stable voltage. AC may be partially converted to DC and sent through exciter windings and rotating rectifiers before final output. This ensures smooth, reliable electricity under all conditions.

Finally, the induced current flows through the generator’s output terminals. It can be AC or DC, depending on design. The electricity is now ready to power devices, equipment, or an entire building.

From spinning rotors to regulated electrical output, a Power Generator follows a precise process to deliver stable electricity wherever it is needed. Knowing how generators work makes it easier to select suitable models, plan proper maintenance, and ensure long-term performance. Whether used for residential backup, commercial operations, or industrial power systems, generators remain essential to energy reliability.

For dependable generator solutions and professional power equipment support, Newtec Power Equipment Co., Ltd. delivers engineered systems designed for efficiency, durability, and real-world power demands.

A generator converts mechanical energy into electrical energy. It allows electricity to flow when the main power source is unavailable or unreliable.

It starts with a prime mover spinning the rotor. The rotor creates a magnetic field, induces current in the stator, and sends regulated electricity to the output.

Generators can use gasoline, diesel, natural gas, propane, wind, water, or gas turbines. The source depends on design and application.

It is the process where a moving magnetic field pushes electrons through wire coils. This movement produces electric current.

AC generators produce alternating current that changes direction. DC generators produce direct current that flows in one direction.